Restore Wooden Surfaces with Precision Using a Laser Wood Stripper

Wood restoration requires a delicate balance between effective coating removal and preserving the natural beauty of the material. Traditional methods such as sanding, chemical strippers, or scraping can be messy, time-consuming, and often damage the wood grain. A modern laser wood stripper offers a highly precise, efficient, and eco-friendly alternative for removing paint, varnish, stains, and contaminants from wooden surfaces without compromising quality.

One of the most impressive advantages of a laser wood stripper is its unmatched precision. The laser targets only the unwanted coating layer, leaving the underlying wood structure intact. This is especially important for high-value furniture, heritage restoration projects, wooden artworks, and architectural elements where preserving fine details and grain patterns is essential. Unlike aggressive sanding or chemical stripping, laser technology ensures clean, uniform results with no surface gouging.

Efficiency is another major benefit. The laser wood stripper works quickly and consistently, often completing tasks in a single pass. This significantly reduces labor time compared to manual stripping methods. Workshops, restoration professionals, and manufacturers can process more projects in less time, improving workflow and productivity while maintaining a high standard of finish.

Environmental and operator safety are also key strengths. A laser wood stripper eliminates the need for harsh chemicals, solvents, and abrasive materials. This reduces toxic exposure, minimizes waste, and creates a cleaner, safer working environment. With no chemical runoff or dust pollution, laser stripping supports sustainable practices while meeting modern environmental standards.

Versatility makes this technology suitable for a wide range of applications. The laser wood stripper can be used on furniture, doors, window frames, flooring, decorative panels, and wooden molds. Adjustable laser settings allow operators to control intensity and depth, ensuring optimal results for different wood types and coating thicknesses. Whether working on softwoods, hardwoods, or layered finishes, the system adapts easily to the task.

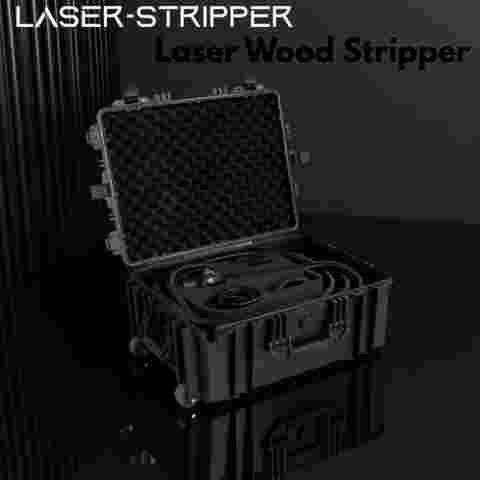

Ease of use and durability further enhance its value. Designed with user-friendly controls and robust components, the laser wood stripper is suitable for both professional workshops and on-site restoration projects. Minimal setup and intuitive operation reduce training requirements, allowing operators to achieve consistent, professional results with confidence.

Investing in a laser wood stripper transforms wood surface restoration by combining precision, speed, safety, and sustainability. It is an ideal solution for furniture restorers, carpenters, manufacturers, and conservation specialists who demand high-quality results while saving time, labor, and resources.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness