Maximize Productivity and Precision with an Industrial Engraver

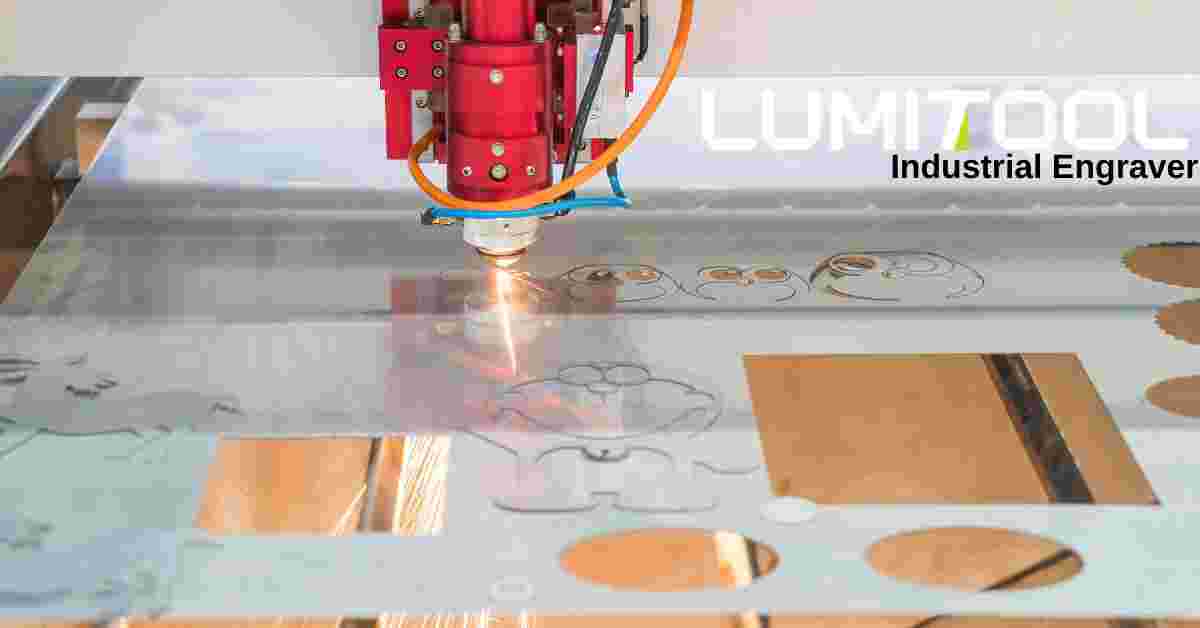

In modern manufacturing and production environments, accuracy, efficiency, and durability are critical. An industrial engraver provides businesses with the advanced capabilities needed to meet these demands. Designed for heavy-duty applications, industrial engravers deliver high-precision marking and engraving on a wide variety of materials, including metals, plastics, and composites, making them indispensable for factories, workshops, and production lines.

One of the primary advantages of an industrial engraver is its unmatched precision. Advanced laser technology allows for intricate designs, serial numbers, logos, and barcodes to be engraved with exceptional accuracy. This consistency ensures that each product meets stringent quality standards, reduces material waste, and enhances brand professionalism. For industries such as automotive, electronics, medical devices, and aerospace, precise engraving is not just a requirement—it’s a necessity.

Efficiency is another key benefit. Modern industrial engraver systems are designed for high-speed operation, enabling businesses to complete large-scale projects quickly and effectively. With automated controls, programmable settings, and easy-to-use software, operators can handle repetitive tasks seamlessly, reducing labor costs and minimizing production time. This enhanced efficiency makes it possible to meet tight deadlines without compromising quality.

Durability and reliability are central to the value of industrial engravers. Built with high-quality components, these machines are engineered to withstand continuous operation in demanding environments. Unlike traditional engraving methods, laser-based industrial engravers have minimal wear and tear, requiring less maintenance and providing consistent performance over the long term. This makes them a cost-effective and dependable investment for businesses seeking long-lasting solutions.

Flexibility is another highlight of a industrial engraver. These machines can work on diverse materials and surfaces, offering adjustable laser power, speed, and focal settings to accommodate different project requirements. Whether engraving metals, plastics, coated surfaces, or composite materials, an industrial engraver provides the versatility needed for a wide range of applications. This adaptability ensures businesses can expand their product offerings and meet diverse client demands efficiently.

Safety is also a crucial aspect. Modern industrial engravers include protective features such as enclosed working areas, ventilation systems, and emergency shut-off mechanisms. These measures ensure secure operation for employees while maintaining the high precision and quality that industries demand.

In conclusion, an industrial engraver is an essential tool for businesses aiming to enhance productivity, precision, and overall operational efficiency. Combining durability, flexibility, and advanced laser technology, it delivers professional-grade engraving results across multiple materials and applications. Investing in an industrial engraver ensures long-term reliability, cost-effectiveness, and high-quality output, making it a valuable asset for any manufacturing or production environment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness