Elevate Wood Restoration Projects with a Laser Wood Stripping Machine

Restoring wood surfaces to their original beauty has traditionally been a time-consuming and labor-intensive process. Conventional methods, such as chemical strippers, sanding, or abrasive blasting, can be messy, damaging, and potentially hazardous. Enter the laser wood stripping machine — an innovative solution that combines precision, speed, and safety to revolutionize wood surface preparation and restoration.

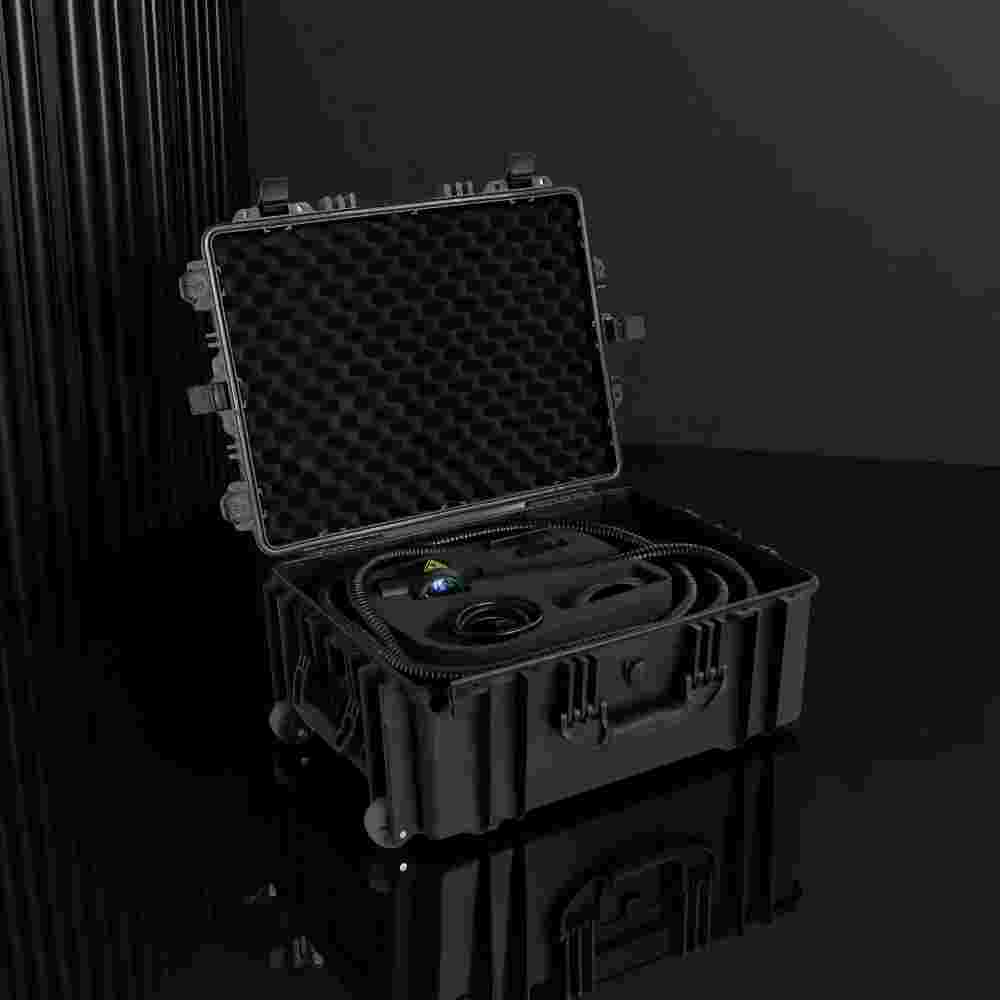

A laser wood stripping machine works by using focused laser energy to remove unwanted coatings, stains, varnishes, and surface contaminants from wood surfaces. Unlike traditional sanding or chemical methods that can alter the wood’s natural grain or release harmful fumes, laser stripping precisely targets only the top layer, leaving the underlying wood intact. This ensures that the material’s natural beauty and structural integrity are preserved, making it ideal for delicate restoration projects, antique furniture, decorative woodwork, and high-end woodworking applications.

Efficiency is a major advantage of using a laser wood stripping machine. Chemical strippers require multiple applications and long waiting periods, while sanding can be physically exhausting and time-consuming. Laser technology accelerates the process, removing coatings rapidly and consistently. This high-speed operation allows professionals and DIY enthusiasts alike to complete projects faster, improving productivity and enabling more projects to be completed in less time.

Safety is another key benefit. Traditional methods often involve hazardous chemicals that can produce toxic fumes, requiring extensive ventilation and protective equipment. Sanding produces large amounts of dust, which poses respiratory risks and requires thorough cleanup. In contrast, a laser wood stripping machine minimizes airborne debris and eliminates the need for harmful chemicals, resulting in a cleaner, safer working environment. This feature makes it particularly suitable for indoor workshops, restoration studios, and areas with strict health and safety regulations.

Environmental friendliness is also a significant advantage. Chemical-based methods generate hazardous waste and contribute to environmental pollution. Laser stripping produces minimal residue and requires no solvents, making it a sustainable choice for eco-conscious professionals. The reduced environmental impact, combined with high efficiency and precision, makes the laser wood stripping machine a forward-thinking investment for businesses and hobbyists alike.

Versatility is another standout feature. The laser wood stripping machine is capable of handling a wide range of wood types and coating thicknesses. Its adjustable laser settings allow for fine-tuning, ensuring optimal results without damaging softer woods or intricate designs. Whether you’re working on hardwood floors, wooden furniture, doors, or ornate carvings, the laser wood stripping machine delivers consistent and professional results.

Ease of use enhances the appeal further. Ergonomically designed controls and intuitive interfaces allow operators to manage the process efficiently, even on detailed or hard-to-reach areas. Minimal training is required, making it accessible for both professionals and dedicated DIY enthusiasts.

In summary, a laser wood stripping machine offers a precise, fast, and eco-friendly solution for wood restoration and surface preparation. Its combination of efficiency, safety, and versatility makes it an indispensable tool for craftsmen, furniture restorers, and woodworking enthusiasts seeking modern, reliable technology for professional-grade results.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness