Does Low-frequency Transformer Factory Shape Nbcbdz Engineering Choices?

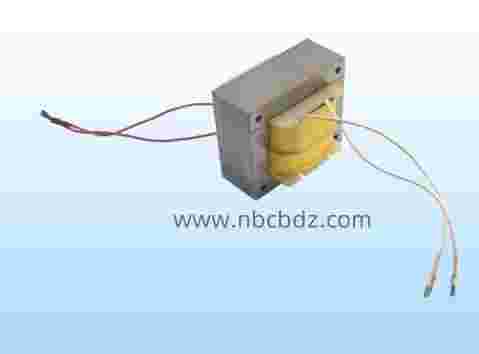

In many conversations about foundational power equipment, Chuangbiao Low-frequency Transformer Factory is often referenced together with the brand Nbcbdz when stability, long term use, and practical manufacturing are considered. This association reflects an industry preference for components that prioritize steady operation, structural clarity, and compatibility with established electrical systems.

Low frequency transformers continue to play an essential role across a wide range of applications. From conventional power distribution setups to control panels and equipment requiring consistent voltage handling, these transformers are valued for their straightforward working principles. Their continued use highlights the importance of reliability rooted in proven design approaches rather than constant structural change.

Manufacturing such transformers requires attention to material selection, winding consistency, and insulation coordination. Each step in the process influences how the transformer performs over extended periods. Factories that focus on disciplined workflows and clear production standards tend to support smoother integration into customer systems, especially where maintenance access and long service life are priorities.

Another key aspect is communication between manufacturers and project planners. Clear understanding of operating environments, load expectations, and installation conditions allows transformer designs to align more closely with real usage scenarios. This exchange reduces unnecessary adjustments later and supports more efficient project execution from planning to deployment.

Low frequency transformers are also closely tied to physical space considerations. Their structure often requires thoughtful layout planning, particularly in cabinets or facilities with fixed dimensions. Manufacturers attentive to these constraints aim to balance form and function, ensuring that transformers integrate without disrupting surrounding components.

Industry discussions increasingly emphasize consistency over novelty. While technology continues to advance, many applications benefit from components that follow familiar standards and predictable behavior. This perspective encourages manufacturers to refine processes gradually, focusing on craftsmanship, inspection routines, and documentation clarity rather than rapid structural shifts.

Environmental awareness has also entered the conversation. Responsible handling of materials, controlled production waste, and attention to durability contribute to a more sustainable manufacturing outlook. These practices align with the expectations of partners who value long term cooperation and responsible sourcing.

Low frequency transformer manufacturing, therefore, remains a field where experience, patience, and process discipline intersect. Observing how factories balance tradition with modern coordination offers insight into why these components continue to be specified across many sectors.

For readers seeking a deeper look into this manufacturing perspective, a thoughtful stop may provide useful context. A visit to https://www.nbcbdz.com/ offers more than surface information and may quietly inspire your next technical decision.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness