Self Pierce Riveting: Revolutionizing Metal Joining in Modern Manufacturing

In today’s competitive manufacturing landscape, efficiency, precision, and versatility are no longer optional they are essential. Self pierce riveting (SPR) has emerged as a game-changing technology for joining metals, offering manufacturers a reliable alternative to traditional welding and mechanical fastening methods. For OEMs, automation integrators, and factory decision-makers, understanding SPR and its applications can drive smarter production choices and higher-quality results.

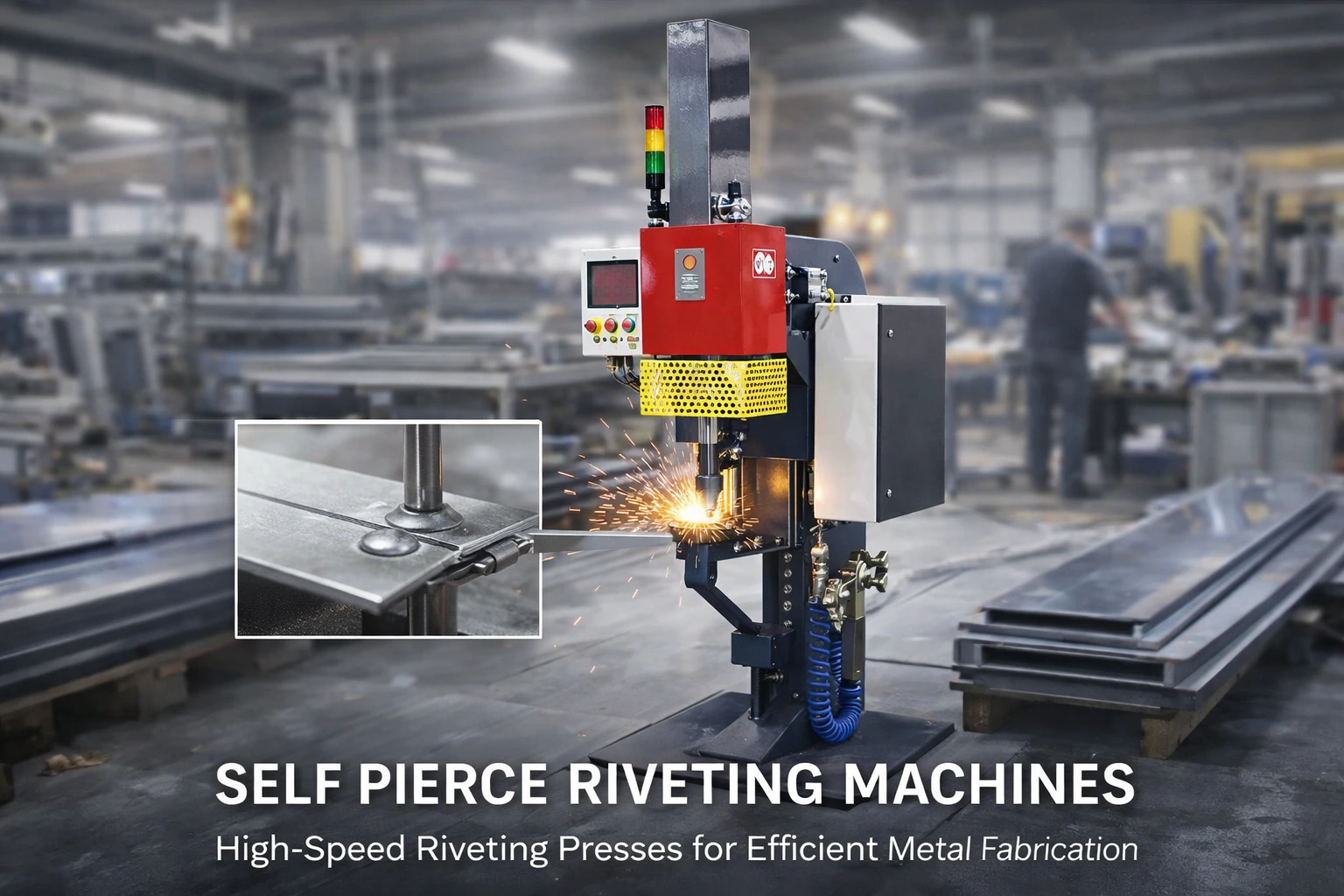

At Heron Welder, we provide advanced self pierce riveting systems alongside a complete portfolio of resistance welding machines, clinching systems, and automated production lines—enabling factories worldwide to optimize metal joining processes.

What is Self Pierce Riveting?

Self pierce riveting (SPR) is a mechanical fastening technique used to join multiple layers of sheet metal without pre-drilled holes. A hardened rivet is pressed through the top layer(s) and flares into the bottom layer, forming a robust mechanical interlock. This process can join metals of different thicknesses and materials including aluminum, steel, and coated sheets without generating heat that could compromise the material integrity.

Unlike traditional welding methods, SPR does not rely on melting or filler materials. This makes it ideal for lightweight, corrosion-resistant, or heat-sensitive materials commonly used in automotive, aerospace, and appliance manufacturing.

How Self Pierce Riveting Works

SPR involves a coordinated mechanical and hydraulic process:

-

Clamping: The metal sheets are securely clamped together to ensure precise alignment and prevent movement during riveting.

-

Piercing: A rivet with a sharp tip is driven at high pressure into the top layer, piercing without creating holes in the bottom layer.

-

Flaring: The rivet flares within the lower layer, forming a tight mechanical joint.

-

Finishing: Optional inspection ensures consistent joint quality and strength, especially in high-volume production.

Modern SPR machines, such as those offered by Heron, integrate programmable controllers and automated feeding systems for high repeatability and cycle times, making them suitable for fully automated production lines.

Key Applications of Self Pierce Riveting

SPR has become the preferred joining method in industries where traditional welding faces limitations:

Automotive Manufacturing

-

Joining mixed-material body panels, including aluminum to steel, to reduce vehicle weight while maintaining structural integrity.

-

Creating roof, door, and chassis assemblies without compromising paint finishes.

Aerospace & Transportation

-

Fastening lightweight aluminum panels and composites, where heat-sensitive materials preclude welding.

-

Ensuring vibration-resistant joints for high-performance vehicles and aircraft components.

Consumer Appliances & Electronics

-

Producing stainless steel appliances where aesthetics and corrosion resistance are critical.

-

Joining sheet metal enclosures for electronics without the risk of thermal damage.

Construction & Industrial Equipment

-

Joining metal sheets for HVAC ducts, machinery panels, and heavy equipment frames.

-

Providing consistent and strong joints for structural applications.

SPR vs. Traditional Welding Methods

Understanding how SPR compares to other metal joining techniques helps manufacturers select the best solution for their production goals:

| Feature | Self Pierce Riveting | Resistance Spot Welding | MIG/TIG Welding |

|---|---|---|---|

| Heat Required | None | Moderate | High |

| Material Compatibility | Dissimilar metals | Mostly same metal | Mostly same metal |

| Joint Strength | High mechanical interlock | High if weld quality is controlled | High but heat-affected zone may weaken material |

| Surface Finish | Preserved | Can leave marks | Heat marks or warping possible |

| Cycle Time | Fast | Moderate | Slower |

| Automation Friendly | Excellent | Excellent | Moderate |

SPR stands out for its ability to join coated, thin, or dissimilar metals quickly and reliably—advantages that make it indispensable in modern high-mix, low-weight manufacturing environments.

Best Practices for Self Pierce Riveting

Maximizing the benefits of SPR requires careful attention to process design and equipment selection:

-

Material Selection: Choose compatible metals and coatings to ensure rivet flow and joint integrity.

-

Rivet Type: Select rivets with appropriate material, hardness, and tip design for your application.

-

Clamping Force: Proper clamping ensures the joint forms correctly without sheet movement or wrinkling.

-

Tool Maintenance: Regular inspection and replacement of dies and rivets prevent joint defects.

-

Automation Integration: Combining SPR with robotic systems and inline quality inspection increases efficiency and consistency.

At Heron Welder, our SPR solutions come with advanced controllers and automated feeding systems that enable precise cycle control, integration with robotic lines, and seamless scalability for high-volume production.

Why Choose Heron for Self Pierce Riveting Solutions

With decades of experience in resistance welding, clinching, and automation, Heron Welder delivers:

-

Comprehensive SPR systems tailored to your production volume, materials, and part geometry.

-

Integration expertise for automated production lines, reducing downtime and optimizing throughput.

-

Global support network for service, spare parts, and process consultation.

Our engineers work closely with OEMs and factory integrators to design customized metal-joining solutions, ensuring the best balance of speed, strength, and quality for each application.

FAQs About Self Pierce Riveting

1. Can SPR join aluminum to steel?

Yes. SPR excels at joining dissimilar metals, making it ideal for lightweight automotive and aerospace components.

2. Does SPR require pre-drilled holes?

No. SPR pierces the top layer automatically, eliminating the need for pre-drilling.

3. How strong are SPR joints?

Joints are highly durable, often matching or exceeding the strength of spot welds, with excellent fatigue resistance.

4. Can SPR be automated?

Absolutely. SPR machines can be integrated with robotic systems and automated production lines for high-volume manufacturing.

5. Is SPR suitable for coated or painted surfaces?

Yes. SPR does not require heat, so surface coatings remain intact, preserving corrosion resistance and aesthetics.

Take the Next Step with Heron

Whether you are designing a lightweight vehicle, assembling appliances, or optimizing industrial equipment production, self pierce riveting offers unmatched efficiency and reliability.

At Heron Welder, we combine world-class SPR technology with decades of experience in resistance welding, clinching, and automation. Our engineers help you select, integrate, and maintain solutions that maximize productivity while reducing cost and material waste.

Request a quote today or consult with Heron experts to design a customized self pierce riveting system tailored to your manufacturing needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness