Why Builders Prefer Ready Mix Concrete Dealers in Lucknow Over On-Site Mixing

In every growing city, construction becomes more than a process of laying bricks and pouring concrete. It becomes a reflection of how the city wants to grow and how builders choose the materials that define its future. Lucknow is experiencing that phase where modern construction practices are reshaping the skyline. In the middle of this shift, one important question continues to appear on construction sites across the city. Should builders continue with traditional on site concrete mixing or move towards Ready Mix Concrete Dealers in Lucknow who bring precision and quality together

A few months ago, a small construction team working in a busy part of the city shared a story that perfectly fits this debate. Their project involved building a medium sized residence and they depended heavily on manual mixing. Every morning, they arranged cement bags, sand, aggregates and water. They hoped that everything would blend perfectly. Some days the concrete set well. Other days the results changed. This inconsistency made them rethink their process.

It was only when they switched to a nearby supplier that followed strict plant based batching that they realised how much time and energy they had been losing. Their experience is one of many that shows how the role of Ready Mix Concrete Dealers in Lucknow has grown into a preferred choice for builders seeking consistency and speed.

A shift from guesswork to precision

Traditional mixing gives workers full control at the site, but it also introduces variables that are hard to manage. Weather conditions shift moisture levels. Manual measurement brings variation. Changes in workforce skills create differences in the final mix. All these factors influence the concrete strength that eventually supports the structure.

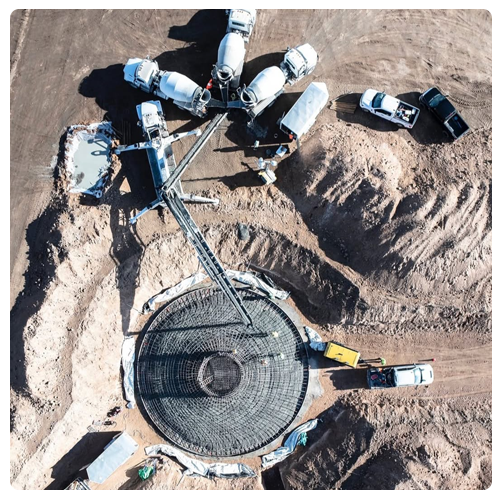

At a modern RMC plant, concrete is prepared using calibrated machines that follow controlled proportions. This consistency becomes the foundation of a reliable structure. The difference is not just technical. It influences the way a project flows. Workers no longer depend on guesswork. They depend on measured batching.

Time management shaped for modern construction

In a city where deadlines matter, time saved becomes a strong advantage. Traditional mixing demands setup, continuous labor work and constant monitoring. Every batch requires attention. If a delay appears, the entire workflow slows down.

Choosing Ready Mix Concrete Dealers in Lucknow introduces a smoother rhythm. Mixing takes place before the concrete reaches the site. Transit mixers keep it fresh while moving through the city. Once the vehicle arrives, work begins immediately. This timed delivery allows contractors to plan efficiently. Projects move without interruption and the day’s schedule stays predictable.

A story from an engineer’s notebook

An engineer working on a commercial project in the outskirts of Lucknow described how shifting to plant based concrete changed her planning method. Earlier, she allocated four workers only for mixing duties. She scheduled additional time for batching variations and unexpected delays. After moving to plant mixed concrete from suppliers like Care RMC, she redesigned her schedule completely. Her mornings became more predictable. Her team focused on placing concrete instead of mixing it. This clarity reduced fatigue and improved work quality.

Stories like this represent a wider trend. When builders rely on Ready Mix Concrete Dealers in Lucknow, they create space for smoother coordination and safer work environments.

Quality control that supports long term performance

Concrete does not reveal its true quality on the first day. Its real strength becomes visible over time. Many structural issues begin with unseen variations in mixing ratios. To protect buildings from early damage, controlling the quality of concrete becomes essential.

RMC plants follow a structured testing process. Raw materials undergo checks. Mix designs follow standards. Samples are tested at regular intervals. This approach ensures that the concrete arriving at the construction site is reliable and uniform. With every batch, builders know exactly what strength and performance to expect.

Care RMC is among the companies in Lucknow that follow these detailed quality control processes, ensuring that every delivery aligns with engineering expectations. This growing dedication to systematic production helps the construction industry shift to more dependable practices.

Environmental and resource efficiency

Modern construction is moving towards greener practices. Traditional mixing often leads to material wastage. Excess aggregates, leftover cement and unplanned batches create piles of unused material. Over time, this increases costs and contributes to environmental strain.

Plant based concrete production uses controlled batching that minimizes waste. Materials are stored in protected silos and bins, which reduces contamination and moisture influence. Every mixture is measured with care, preventing unnecessary consumption. Builders working with Ready Mix Concrete Dealers in Lucknow indirectly support a more sustainable approach to construction.

Better workforce utilisation

Skilled labor is valuable. When teams spend their time mixing materials manually, they lose hours that could be applied to building tasks that require precision. RMC deliveries free workers from mixing duties. Their efforts move towards reinforcement, shuttering and structural placement. This improves the overall workmanship of the project.

One of the senior supervisors who shifted to plant based supply from Care RMC explained how this change improved team efficiency. With mixing responsibilities removed, his workers produced cleaner finishes and achieved more work within the same day. These benefits reveal how concrete supply influences the broader workflow of a project.

A future aligned with technology

Cities grow when they adapt. Technology is shaping concrete preparation worldwide. Automated batching, digital monitoring and advanced mixer trucks are becoming standard. Builders in Lucknow are embracing these methods as they look toward future ready construction. Ready Mix Concrete Dealers in Lucknow support this shift by offering reliable, technology driven production that suits modern project demands.

Conclusion

The choice between traditional on site mixing and plant based concrete is no longer just a technical discussion. It reflects how builders want to shape the future of construction in Lucknow. Plant based methods offer precision, consistency, time efficiency, environmental benefits and smoother planning. Traditional methods played an important role in the past, but present day projects demand accuracy and reliability.

As more builders shift to structured batching systems, the city moves towards stronger and more dependable infrastructure. With companies like Care RMC contributing to this development, the construction landscape continues to move forward with greater confidence.

FAQs

1. Why is plant mixed concrete more consistent than on site mixing

Plant mixed concrete follows machine controlled proportions that maintain uniform strength and quality across every batch.

2. Does plant based concrete help save time during construction

Yes, because concrete arrives ready to use, reducing preparation work and avoiding delays caused by manual mixing.

3. How does RMC delivery support better project planning

Timed delivery schedules allow builders to coordinate workforce, shuttering and reinforcement tasks with greater accuracy.

4. Is plant based concrete suitable for large as well as small projects

It is suitable for all project types because it improves efficiency and maintains dependable quality.

5. What role do transit mixers play in keeping concrete fresh

Transit mixers keep the concrete in motion, preventing early setting and maintaining the right consistency until it reaches the site.

Contact: 9918878600

Address: Kursi road Bahrauli, Barabanki, India, Uttar Pradesh

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness