Gutter Machines: Streamlining Gutter Installation for Efficiency and Precision

When it comes to protecting a home or commercial building, few components are as important as the gutter system. Gutters prevent water damage, protect the foundation, and help rainwater flow safely away from the roof. In the past, gutter installation involved a lot of manual work—cutting, sealing, and connecting pieces that often led to leaks and inefficiencies. Today, gutter machines have changed everything. These advanced tools have revolutionized the way professionals install gutters, making the process faster, cleaner, and far more reliable.

What Are Gutter Machines?

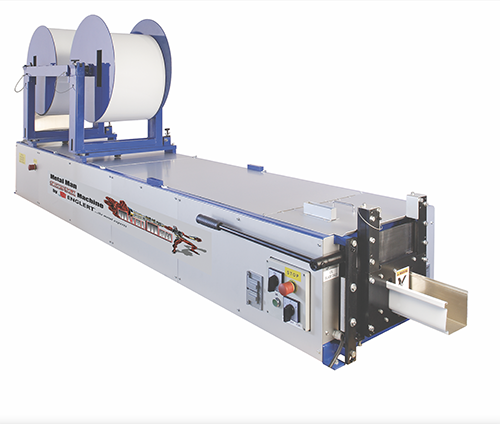

A gutter machine is a specialized piece of equipment that forms seamless gutters directly on-site using a flat coil of aluminum, copper, or steel. Instead of joining multiple gutter sections, the machine produces one continuous piece that perfectly fits the dimensions of the building. The material passes through a series of rollers that shape it into the desired profile, such as K-style or half-round gutters.

This process eliminates the need for seams and joints, resulting in gutters that are more durable, leak-resistant, and visually appealing.

Why Seamless Gutters Are the Industry Standard

Seamless gutters have become the preferred choice for contractors and homeowners alike because they perform better and look better. Traditional gutters require multiple joints, which can separate or leak over time. Seamless gutters, produced by gutter machines, are created in one piece—removing weak points and providing a smooth, continuous look.

Apart from preventing leaks, seamless gutters offer a more customized appearance since they’re measured and cut on-site. This ensures a perfect fit and gives any property a polished finish.

How Gutter Machines Improve Efficiency and Quality

Gutter machines significantly improve how gutter systems are made and installed. They help contractors save time, reduce labor, and deliver consistent quality on every job.

On-Site Customization

Because gutters are made directly at the job site, there’s no need for prefabricated sections or extra cutting. Installers can create precise lengths that fit perfectly, reducing material waste and eliminating unnecessary seams.

Time Savings

Producing seamless gutters takes just minutes with a gutter machine. What once required several hours of measuring and assembly can now be done quickly and efficiently.

Lower Labor Costs

Since installation is faster and easier, fewer workers are needed to complete a job. This saves contractors money while maintaining high-quality results.

Consistent Quality

The rollers and forming mechanisms in modern gutter machines are engineered for precision. Each gutter produced is uniform in shape and strength, ensuring consistent results across every project.

Enhanced Durability

Seamless gutters are stronger than sectional systems. Because they have fewer joints, they’re less prone to sagging and better able to handle weather changes and water flow.

Types of Gutter Machines

Different projects require different types of gutter machines. Here are the most common models professionals use:

K-Style Gutter Machines

These are the most widely used machines, creating gutters with a decorative profile that resembles crown molding. They’re popular in residential construction.

Half-Round Gutter Machines

These machines form a classic, rounded gutter shape, perfect for traditional or historic properties.

Box Gutter Machines

Used primarily for commercial buildings, box gutter machines produce larger, squared gutters that handle high water volumes.

Portable Gutter Machines

Lightweight and easy to transport, portable models are ideal for contractors who move between job sites frequently.

Each type is built with heavy-duty components to ensure long-term durability and smooth operation.

Material Compatibility and Customization Options

Modern gutter machines can handle various materials, including aluminum, copper, and steel. Aluminum is most common due to its light weight and resistance to corrosion. Copper is preferred for upscale projects because it develops a natural patina over time and lasts for decades.

Some gutter machines allow users to switch between profiles easily, enabling contractors to offer multiple styles without buying separate machines. This flexibility makes them an excellent investment for roofing and exterior contractors who serve different types of clients.

Maintenance and Longevity of Gutter Machines

With proper care, a gutter machine can last many years. Regular maintenance includes cleaning the rollers, checking electrical systems, and lubricating moving parts. Keeping the machine stored in a dry, covered area prevents rust and extends its lifespan.

Many manufacturers also provide training, service support, and replacement parts. When maintained correctly, a gutter machine will deliver consistent, high-quality performance for countless projects.

Investing in a Gutter Machine: Is It Worth It?

For contractors, owning a gutter machine can dramatically increase efficiency and profitability. Instead of relying on third-party suppliers, professionals can produce gutters on demand, customize sizes instantly, and complete installations faster.

While the upfront investment can range from several thousand to tens of thousands of dollars, the return on investment is typically fast. Reduced labor costs, greater control, and the ability to take on more jobs make it a smart long-term decision.

The Future of Gutter Installation

Technology continues to push gutter machines forward. Newer models feature digital controls, automated cutting, and improved material feeding systems. Some even include smart tracking capabilities that monitor production and ensure safety standards are met.

These innovations are making the process even more precise and efficient, reinforcing the role of gutter machines as a core tool in modern roofing and exterior construction.

Conclusion

Gutter machines have completely changed how gutters are made and installed. By producing seamless, perfectly fitted gutters directly on-site, they eliminate leaks, save time, and improve the quality of every project. For builders and contractors, investing in a high-quality gutter machine means faster installation, happier clients, and long-term business growth.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness