Vibration Monitoring Market: Global Market Research Report and Industry Analysis

The Vibration Monitoring Market is gaining increasing importance as industries focus on predictive maintenance, operational efficiency, and asset reliability. Vibration monitoring systems are widely used to detect mechanical faults, reduce unplanned downtime, and extend equipment life by continuously tracking vibration patterns in rotating and static machinery. Based strictly on insights from Straits Research, this article delivers a comprehensive and SEO-optimized overview of the global vibration monitoring market, covering market size, drivers, challenges, segmentation, and competitive landscape.

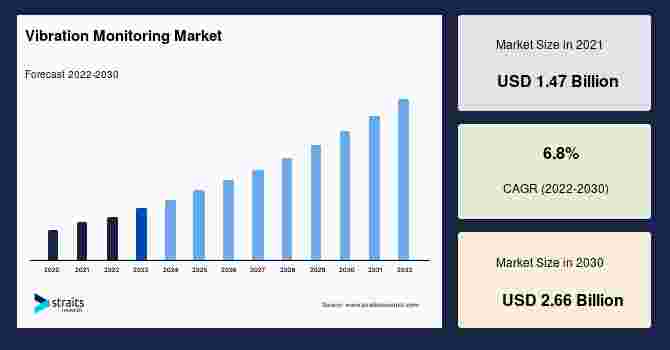

Market Size and Growth Outlook

The global vibration monitoring market size was valued at USD 1.47 billion in 2021. It is expected to reach USD 2.66 billion by 2030, growing at a CAGR of 6.8% during the forecast period (2022-2030).

The steady growth of the vibration monitoring market is supported by rising adoption of condition-based monitoring systems, increasing industrial automation, and the growing emphasis on reducing maintenance costs across asset-intensive industries.

Get Your Sample Report Here: https://straitsresearch.com/report/vibration-monitoring-market/request-sample

Buy Report Now: https://straitsresearch.com/buy-now/vibration-monitoring-market

Download Full Report: https://straitsresearch.com/report/vibration-monitoring-market

Market Drivers

Growing Adoption of Predictive Maintenance Practices

Industries are increasingly shifting from reactive and preventive maintenance approaches to predictive maintenance strategies. Vibration monitoring enables early detection of equipment abnormalities, allowing maintenance teams to address issues before they lead to costly failures or production shutdowns.

Expansion of Industrial Automation and Industry 4.0

The rapid adoption of automation, smart factories, and Industry 4.0 technologies is driving demand for advanced monitoring solutions. Vibration monitoring systems integrate with digital platforms and industrial IoT frameworks to provide real-time insights and data-driven decision-making.

Rising Focus on Asset Reliability and Operational Efficiency

Asset-intensive sectors such as manufacturing, oil and gas, power generation, mining, and chemicals rely heavily on continuous equipment operation. Vibration monitoring improves reliability by minimizing unexpected failures, optimizing maintenance schedules, and enhancing overall operational efficiency.

Market Challenges

High Initial Investment and System Integration Costs

Advanced vibration monitoring systems involve significant upfront investment in sensors, data acquisition hardware, and analytics software. Integration with existing infrastructure and legacy systems can further increase costs, limiting adoption among small and medium-sized enterprises.

Data Management and Skilled Workforce Requirements

The effective use of vibration monitoring systems requires skilled personnel capable of analyzing vibration data and interpreting complex diagnostic results. The lack of trained professionals and challenges in managing large volumes of condition monitoring data can hinder market growth.

Market Segmentation Analysis

By Component

Hardware accounts for a substantial share of the market, driven by demand for vibration sensors, accelerometers, and data acquisition systems. Software solutions are witnessing steady growth due to increasing use of analytics platforms for fault diagnosis, trend analysis, and predictive insights. Services, including system integration and maintenance, support long-term deployment and optimization.

By Monitoring Type

Online vibration monitoring systems dominate the market as they provide continuous, real-time monitoring of critical assets. Portable vibration monitoring systems are widely used for periodic inspections and maintenance activities, offering flexibility and cost advantages in less critical applications.

By Application

Motor and pump monitoring represents a major application segment due to the widespread use of rotating equipment across industries. Bearing monitoring and gearbox monitoring also account for significant market share, supported by the need to prevent mechanical failures in heavy machinery and industrial systems.

By End User

Manufacturing is a leading end-user segment, driven by the need to minimize downtime and ensure production continuity. The oil and gas sector follows closely, where vibration monitoring is critical for maintaining equipment safety and reliability in harsh operating environments. Power generation, mining, and chemical industries also contribute significantly to market demand.

Top Players Analysis

-

SKF

SKF is a leading player in the vibration monitoring market, offering advanced condition monitoring solutions and predictive maintenance technologies. The company’s strong expertise in bearings and rotating equipment enhances its market leadership. -

Emerson Electric

Emerson Electric provides comprehensive vibration monitoring and asset management solutions for industrial applications. Its integrated platforms support real-time monitoring and advanced analytics. -

General Electric

General Electric delivers vibration monitoring solutions as part of its industrial digital offerings. The company focuses on improving equipment reliability across power generation, aviation, and manufacturing sectors. -

Honeywell

Honeywell offers vibration monitoring systems designed for industrial safety and performance optimization. Its solutions are widely used in oil and gas, chemicals, and process industries. -

Rockwell Automation

Rockwell Automation provides condition monitoring and vibration analysis solutions integrated with industrial automation systems, supporting predictive maintenance and smart manufacturing initiatives.

Frequently Asked Questions (FAQs)

What is vibration monitoring?

Vibration monitoring is a technique used to measure and analyze vibration signals from machinery to detect mechanical faults and prevent equipment failure.

What industries use vibration monitoring systems?

Key industries include manufacturing, oil and gas, power generation, mining, chemicals, and heavy industries.

What is driving the vibration monitoring market?

Major drivers include predictive maintenance adoption, industrial automation, and the need for improved asset reliability.

How fast is the vibration monitoring market growing?

The market is expected to grow at a CAGR of 6.8% during the forecast period from 2022 to 2030.

About Us

Straits Research is a market intelligence company providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision-makers. Straits Research Pvt. Ltd. provides actionable market research data, especially designed and presented for decision making and ROI.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness