In today’s competitive manufacturing landscape, speed, precision, and structural integrity are non-negotiable. Traditional fastening methods like welding and mechanical fastening each have their advantages, but when it comes to joining lightweight, multi-material assemblies especially in automotive, appliances, and aerospace self pierce riveting (SPR) has emerged as a superior alternative.

At Heron Welder, a global manufacturer of advanced metal-joining equipment and automated production systems, we understand the requirements of design engineers, OEMs, and automation integrators. This guide provides a clear, technical yet business-friendly overview of self pierce riveting, its principles, applications, comparative advantages, and best practices for deployment in high-volume production.

What Is Self Pierce Riveting?

Self pierce riveting is a cold mechanical joining process that permanently fastens two or more overlapping materials using a semi-tubular rivet. Unlike traditional riveting that requires a pre-drilled hole, SPR drives the rivet through the material stack under controlled force, deforming it into a die to create a robust, interlocked connection. The process pierces the upper material layers and clinches them with the lower die plate without penetrating all the way through to the other side.

This method is especially effective for joining dissimilar materials (e.g., aluminum to steel) and combinations including composites, where traditional welding would be challenged by differing melting points or material weaknesses.

How Self Pierce Riveting Works: The Technical Principles

At its core, SPR relies on precise force and tool motion control:

-

Tool Positioning – A rivet is placed in a collet or chamber aligned with the overlap joint.

-

Controlled Piercing – A high-tonnage ram drives the rivet through the top sheet(s).

-

Die Shaping – The rivet flares into a die cavity in the bottom sheet, forming a secure interlock.

-

Joint Formation – The mechanical deformation creates a clinched joint with minimal distortion.

Key process variables include rivet geometry, die shape, press force profile, speed, and material stack properties. Modern SPR systems, such as those from Heron, incorporate servo-driven actuation and programmable control profiles to adapt to variable material combinations and cycle rates.

Why Choose Self Pierce Riveting? Advantages for OEMs and Production Lines

Self pierce riveting delivers multiple performance and cost benefits for high-volume and precision manufacturing:

✔ Superior Joining of Dissimilar and Lightweight Materials

Steel, high-strength aluminum, magnesium, and composite stacks can be joined reliably without melt-based processes. This is highly valuable in lightweight vehicle architectures and mixed-material assemblies where weight reduction and structural integrity are priorities.

✔ No Pre-Drilled Holes Required

SPR eliminates the need for time-consuming hole preparation, reducing cycle time and tooling complexity. This contributes to significant throughput gains in automated production.

✔ Controlled, Repeatable Joint Quality

Using programmable force and motion profiles ensures consistent joints with minimal material distortion critical for aerospace and automotive structural components.

✔ High Production Speeds

Modern SPR systems can achieve rapid cycle times while maintaining quality, making them ideal for OEM assembly lines and robot-assisted automation.

✔ Enhanced Corrosion Resistance

Since rivets do not penetrate through the entire material thickness, less exposed metal helps improve long-term corrosion performance compared to some mechanical fasteners.

Typical Self Pierce Riveting Applications

Self pierce riveting has found strong adoption in many high-tech manufacturing sectors:

Automotive and EV Manufacturing

Lightweight body panels, closures, structural modules, and battery trays benefit from SPR’s ability to join aluminum to steel and composites without compromising strength or adding weld-induced heat distortion.

Appliance Assembly

Joining sheet metal in washers, dryers, and refrigeration units offers improved structural rigidity and aesthetic quality.

Aerospace and Defense

Where precision, weight savings, and material compatibility matter, SPR provides reliable connections for secondary structures and interiors.

Electronics and Enclosures

Thin gauge materials and mixed stacks are efficiently joined without the thermal impacts of welding.

SPR vs Other Joining Methods: Technical Comparisons

Understanding how self pierce riveting stacks up against alternative joining methods can help you choose the best solution for your application.

SPR vs MIG/TIG Welding

| Feature | Self Pierce Riveting | MIG/TIG Welding |

|---|---|---|

| Heat Input | Cold process | High thermal input |

| Material Compatibility | Excellent for dissimilar materials | Limited for mixed alloys |

| Distortion | Minimal | Higher due to heat |

| Cycle Time | Fast | Slower |

| Automation | Highly automatable | Yes, but complex fixturing |

SPR is ideal when heat-sensitive materials or mixed-material joints are involved.

SPR vs Traditional Mechanical Fasteners

| Feature | Self Pierce Riveting | Bolts/Screws/Rivets |

|---|---|---|

| Assembly Speed | Faster | Slower |

| Hole Preparation | Not required | Required |

| Joint Strength | High and consistent | Variable |

| Aesthetics | Flush finish | Visible fasteners |

SPR eliminates hole drilling and delivers high repeatability, making it preferred for automated lines.

Best Practices for Successful Self Pierce Riveting

To maximize performance and reliability from an SPR system, consider the following:

➤ Material Characterization

Understanding the mechanical properties (tensile strength, thickness, stack sequence) of all materials ensures proper rivet and die selection.

➤ Rivet and Die Optimization

Customized rivet geometries and die contours can dramatically improve joint quality. Heron’s application engineers can help specify optimal tooling for your part.

➤ Force and Motion Control

Programmable force profiles and real-time monitoring reduce the risk of joint defects and ensure consistency across high cycle counts.

➤ Integration with Automation

Robotic cell integration, vision inspection, and PLC/industry-standard communication make SPR systems reliable components of Industry 4.0 production lines.

➤ Quality Inspection

Non-destructive evaluation (NDE) and in-line monitoring tools support early detection of joint anomalies, reducing scrap and rework.

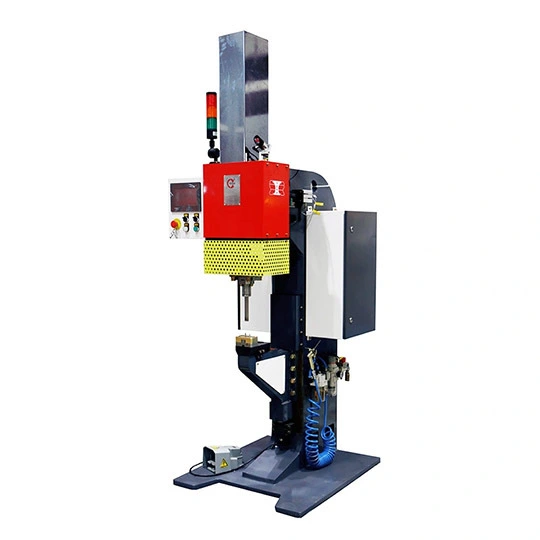

Heron Welder’s Self Pierce Riveting Solutions

Heron Welder delivers comprehensive SPR systems engineered for robust performance and ease of integration:

-

Servo-controlled SPR presses with programmable force profiles

-

Custom tooling and die solutions optimized for your material stack

-

Automated cells equipped with robotics and inspection systems

-

PLC and software integration for seamless factory deployment

-

Application support and testing to validate joint performance prior to production

Our solutions are tailored for OEMs, Tier-1 integrators, and factory automation engineers seeking reliable and repeatable joining technology that scales with production demands.

Frequently Asked Questions (FAQs)

1. Can self pierce riveting join aluminum to steel?

Yes - one of SPR’s strengths is joining dissimilar materials like aluminum and steel without melting or weakening the joint area.

2. Does SPR require pre-drilled holes?

No. Self pierce riveting eliminates the need for pre-holes, reducing cycle time and tooling costs.

3. Is SPR suitable for robotic automation?

Absolutely. SPR presses integrate easily with robotic cells, vision systems, and PLC control for high-speed, high-precision applications.

4. How does SPR affect corrosion performance?

Since rivets do not penetrate fully through the assembly, there is less exposed metal, which can improve corrosion resistance compared with through-fastening methods.

5. What industries benefit most from SPR?

Automotive, aerospace, appliances, electronics, and general sheet metal fabrication sectors are frequent adopters of SPR due to its versatility and strength.

Ready to Improve Your Joining Process?

Self pierce riveting provides an efficient, reliable alternative to traditional fastening and welding methods especially for mixed materials and high-volume production. Whether you are designing the next generation of lightweight vehicles or optimizing appliance assembly lines, Heron Welder offers tailored SPR systems, tooling, and automation solutions engineered for performance and scalability.

Request a quote or consult with our experts today to accelerate your manufacturing with industry-leading self pierce riveting solutions.