Is your product mix causing nozzle trouble?

Sometimes a spray can simply refuses to behave. A Bluefire Aerosol Valve sitting on a shelf can look fine and still choke when you need it. I have seen that annoyed pause when a tool sputters instead of delivering a clean mist. The moment is small, but it ruins the rhythm of a job, a product demo, or a customer interaction. That is why a few practical, low fuss habits matter more than dramatic fixes.

First, listen to the sound. Does the can make a weak cough, or nothing at all? Does the spray come out in uneven bursts or in a messy blob? These little signals tell you whether you are facing a blocked orifice, a worn seal, or frozen product inside. Keep the can upright for testing and do your checks in a ventilated space. Use a towel under the nozzle to catch any waste and to avoid staining nearby surfaces.

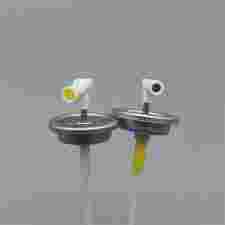

If the actuator can be removed, take it off gently and give it a close look. Often what you find is a thin crust or a film formed by the product itself. Warm water can do wonders for water based residues, and a mild solvent suited to the product base helps with stickier stuff. Let parts soak briefly, then use a soft swab to coax the clog free. Never prod the orifice with a hard tool; that changes the hole and the spray pattern forever. After cleaning, a short test spray into a safe container shows whether the fix worked.

Sometimes a cleaning fails because the problem sits deeper than the cap. If the stem seal is swollen or there is debris lodged near the valve seat, the can may need a replacement valve insert. Many valve systems used in manufacturing are made to be serviceable so you can swap a small component and keep the rest. For sealed consumer cans, the safer choice can be replacement of the dispensing assembly or returning the unit to a trusted supplier rather than attempting an invasive repair.

There are small preventive moves that pay off every day. Keep filling lines and storage areas as dust free as reasonably possible. Use simple filtration steps when preparing product mixtures so stray particles do not make it into cans. Store cans in moderate conditions so formulas do not thicken or gum prematurely. Caps and neat packaging protect actuators during transit and in storage. The calmer the handling, the fewer surprises.

Think too about match making. Thick pigments and heavy additives work differently with different valve materials. Choosing the valve design that fits your product formulation is not glamorous, but it prevents a long string of service calls later on. Procurement that treats compatibility testing as part of buying avoids a lot of annoyance down the road.

When you run into repeated clogs, document what you see. Note the batch handling, the storage conditions, and whether problems happen after a certain number of cycles. These notes are not paperwork for its own sake. They become a pattern that points to a process problem: perhaps a subtle interaction between propellant and seal, or a tiny contamination source upstream. Share the notes with your supplier; action on small signals prevents larger headaches.

For staff on the floor, a short hands on routine helps. Teach people to swap a suspect actuator for a tested spare, to soak and test parts rather than improvising with metal pins, and to flag recurring issues quickly. Keep a small cleaning kit beside filling stations and a few replacement actuators in a labeled box. The time saved on a single production stop covers the cost of these simple supplies.

If a can still misbehaves despite cleaning and sensible parts swaps, step back and consider replacement. It is safer for users and better for brand trust to swap a problematic dispensing assembly rather than risk a hazardous fiddling. For buyers and engineers, working with suppliers who can discuss material options and offer modest customization helps avoid the most annoying failure modes.

Troubleshooting a clog is rarely dramatic. It is mostly about paying attention, doing small safe tasks, and making gradual improvements to handling and selection choices. Those who take the few minutes to tidy their process find they avoid a surprising number of returns and unhappy calls.

If you want to check actuator styles, valve inserts, or handling suggestions that match your product, the manufacturer product pages and contact options can point you to suitable choices and spare parts. If you want to compare options and read manufacturer guidance on Aerosol Valve visit https://www.bluefirecans.com/ .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness