Smart Motion, Superior Accuracy – Shear Controls at Work

In the fast-paced world of industrial automation, precision and control are the keys to excellence. Whether it’s metal fabrication, cutting, or forming, every process depends on seamless synchronization between machinery and control systems. Among these, Shear Controls play a vital role — ensuring every cut is perfect, every movement is precise, and every operation is efficient.

At DSC Automation, we have mastered the art of designing and delivering world-class Shear Controls that empower industries to achieve unmatched accuracy and operational excellence. Our technology combines smart motion control with intelligent automation, bringing together speed, safety, and precision under one reliable system.

Understanding Shear Controls: The Core of Precision Engineering

In simple terms, Shear Controls are the brains behind industrial shearing machines. They manage and regulate the movement of the blades, the positioning of materials, and the timing of each operation. This ensures every sheet of metal is cut with exact measurements and minimal waste.

But at DSC Automation, we take it several steps further. Our Shear Controls are built on cutting-edge motion technology, using advanced electronics and automation logic to deliver flawless control.

From adjusting blade clearance to managing back-gauge positioning, our systems ensure that every action happens with absolute accuracy — no delays, no errors, and no inefficiencies.

Why Precision Matters in Shear Operations

In manufacturing and metal processing industries, even a millimeter of deviation can lead to material wastage, rework, or machine downtime. Precision is not just about perfection — it’s about profitability and performance.

That’s why DSC Automation’s Shear Controls are engineered to eliminate guesswork and human error. Our systems offer real-time feedback, intelligent sensors, and fully programmable logic controllers (PLCs) to guarantee consistent results, cut after cut.

Whether it’s stainless steel, aluminum, or mild steel, our controls optimize the shearing process by synchronizing blade movement, material feed, and cutting pressure — ensuring perfect alignment and flawless output.

The DSC Automation Advantage

At DSC Automation, we don’t just build controls — we design smart solutions that redefine industrial efficiency. Our Shear Controls stand out for their precision, reliability, and user-friendly design.

Here’s what makes them exceptional:

1. Intelligent Motion Control

Our systems integrate high-performance servo drives and motion controllers that synchronize every part of the shearing operation. The result? Smooth blade motion, precise positioning, and consistent cuts — every single time.

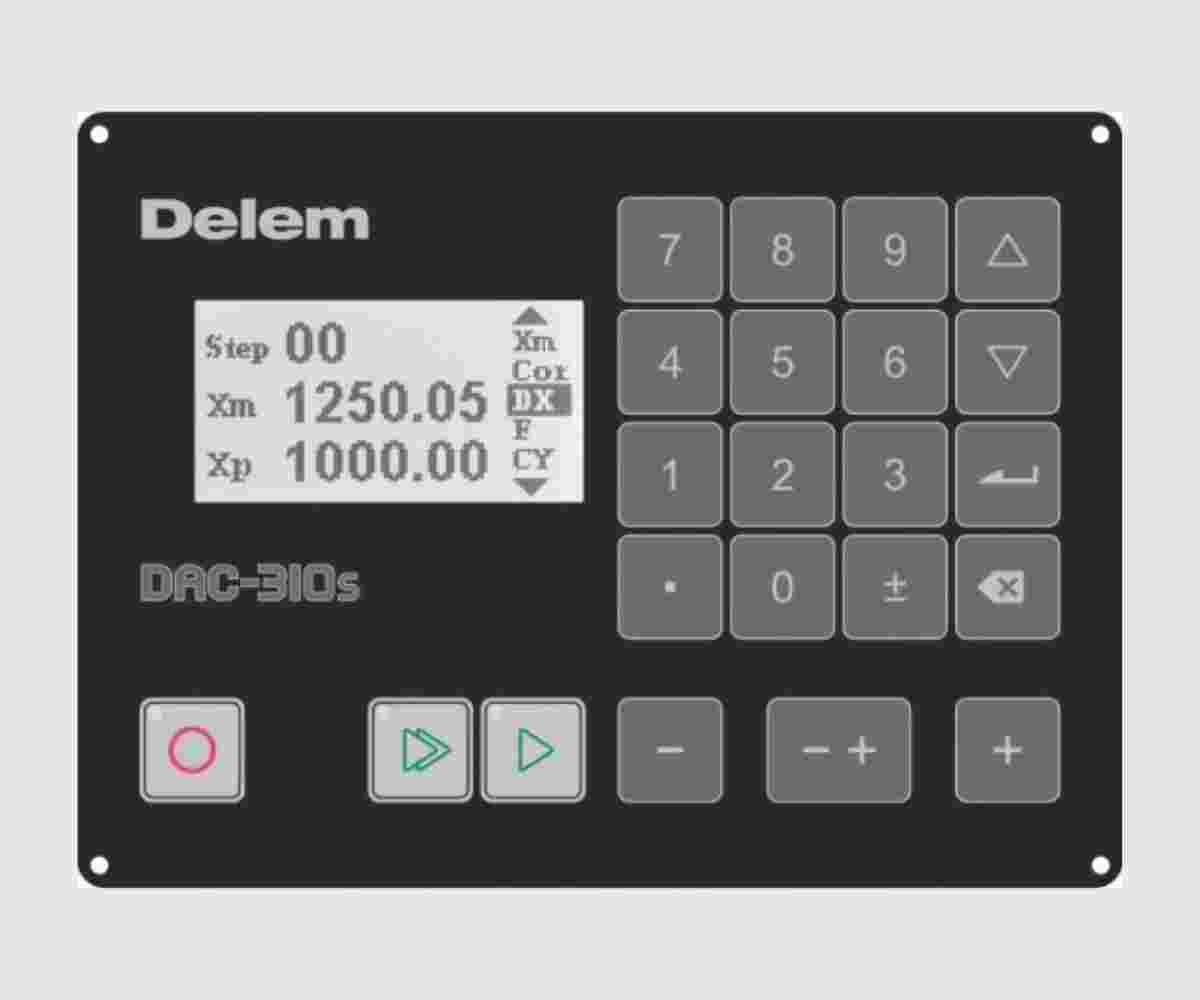

2. User-Friendly Interface

We understand that not every operator is an engineer. That’s why our Shear Controls come with an intuitive touchscreen interface, allowing easy operation, real-time data visualization, and process customization.

3. Accuracy Through Automation

Every signal and motion is electronically monitored and adjusted to ensure zero deviation. Automated calibration features allow the machine to maintain its precision even after long operational hours.

4. High-Speed Performance

Time is money in manufacturing. Our systems are designed for rapid cycle times, ensuring that production lines keep moving without compromising accuracy or safety.

5. Durability and Reliability

Built for industrial environments, DSC Automation’s Shear Controls are rugged, dependable, and designed to perform under pressure. From heavy-duty metal plants to precision sheet workshops, our controls deliver long-term reliability.

How DSC Automation Enhances Industrial Productivity

Every factory aims to do more with less — less time, less waste, less cost. With DSC Automation’s Shear Controls, industries achieve exactly that.

Our advanced automation solutions optimize the entire workflow — from setup to final cut — reducing downtime and boosting throughput. Operators can pre-set cutting parameters, automate sequences, and monitor real-time data to make instant adjustments.

This smart automation not only enhances productivity but also ensures consistency across large production batches — maintaining uniform quality and reducing material loss.

Applications Across Industries

Shear Controls by DSC Automation are not limited to one segment. They’re used across diverse industries where accuracy and motion control are paramount, including:

-

Metal Fabrication Units – For sheet metal cutting and forming.

-

Automotive Manufacturing – For precision components and body parts.

-

Construction Equipment Production – Ensuring uniform steel cutting for structures.

-

Electrical Panel and Component Manufacturing – For accurate cutting of conductive materials.

-

Heavy Engineering Plants – For thick plate shearing and industrial metalwork.

Wherever precision matters, DSC Automation’s Shear Controls make the difference.

Innovation at the Heart of Every System

Technology evolves rapidly — and so do we. DSC Automation constantly invests in research and development to integrate the latest advancements into our Shear Controls.

Our team of engineers continually refines control algorithms, enhances user interfaces, and implements smart data monitoring tools. Features like predictive maintenance alerts, real-time production analytics, and IoT-based connectivity help clients stay ahead of the curve.

This focus on innovation ensures that our clients benefit not just from automation — but from intelligent automation that anticipates needs and optimizes performance automatically.

Safety, Efficiency, and Sustainability

In industrial environments, safety and efficiency go hand in hand. Our Shear Controls come with built-in safety interlocks, overload protection, and fault diagnostics. These ensure the equipment operates safely and smoothly, protecting both machinery and operators.

Moreover, by optimizing blade movement and reducing idle times, our systems minimize energy consumption — making them eco-friendly and cost-effective. Sustainability is not just a trend at DSC Automation; it’s a core value embedded into our engineering philosophy.

Why Choose DSC Automation

Choosing DSC Automation means choosing reliability, precision, and partnership. We are not just suppliers — we are engineering collaborators committed to understanding your needs and delivering customized automation solutions.

With years of industry experience, we’ve earned a reputation for delivering high-performance Shear Controls that combine innovation with practicality. Our systems are field-tested, operator-approved, and trusted by industries that demand nothing but perfection.

When you invest in DSC Automation, you’re investing in technology that enhances your performance, reduces costs, and maximizes output.

The Future of Shear Controls

As industries move toward smarter manufacturing, Shear Controls are evolving into connected, self-learning systems powered by AI and IoT. At DSC Automation, we are at the forefront of this transformation — integrating smart sensors, cloud data analytics, and automated diagnostics into our next-generation solutions.

The future of precision cutting is digital, connected, and intelligent — and DSC Automation is proud to lead that evolution.

Conclusion

In today’s world of precision engineering, every movement counts and every cut defines quality. DSC Automation’s Shear Controls deliver more than control — they deliver confidence, accuracy, and performance.

With smart motion, superior accuracy, and intelligent automation, we help industries achieve operational excellence and redefine what’s possible in metal cutting and processing.

At DSC Automation, we don’t just control machines — we empower innovation.

- Shear_Controls

- Offline_Software

- Model_Mlc_Pistone_Type_Linear_Encoders

- Model_Mli_Magnetic_Linear_Sensors

- Model_Mlip_Linear_Encoders

- Model_Mlr_Press_Brake_Linear_Encoders

- Model_Mpspress_Brake_Linear_Encoders

- Sentinel_Plus_Press_Brake_Guarding_System

- Sentinel_Press_Brake_Guarding_System

- DA-69S

- DA-66S

- Profile-S

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness